AUTOMOTIVE SOLUTIONS

Our dedicated automotive team focuses on developing solutions that bring your concepts and ideas to market in an expeditious manner.

🚘 SOLUTIONS BY MARKET MANUFACTURING

Auto parts solutions can vary by market, reflecting the specific needs and demands of different segments within the automotive industry. As Manufacturers, we focus on producing high-quality, standardized parts that meet stringent OEM specifications. This market caters to auto body shops and collision repair centers that need replacement parts to repair damaged vehicles.

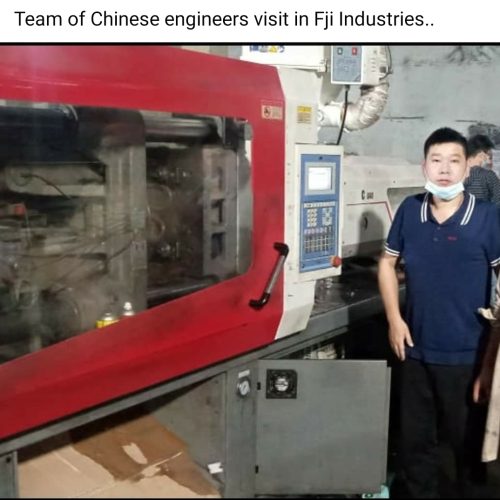

Auto Injection Molding

Manufacturing auto parts using auto injection molding machines involves a highly automated and efficient process. Here’s a simplified overview of the key steps involved in producing parts through this method:

- Design and Mold Creation

- Material Selection

- Injection Molding Setup

- Injection

- Cooling

- Ejection

- Trimming and Finishing

- Quality Control

- Packaging and Shipping

For questions or more information contact us today:

Automotive Plastic molds

Automotive plastic molds for car bodies are complex and precision-engineered tools used in the manufacturing of various plastic components and panels that make up a vehicle’s exterior. These molds are instrumental in achieving the desired shape, size, and finish of automotive body parts. Here’s an overview of the key aspects of automotive plastic molds used for car bodies:

- Design and Development: The process begins with the design of the plastic mold. Engineers create detailed 3D computer-aided design (CAD) models of the car body components, such as fenders, doors, hoods, and other exterior panels. The mold design includes considerations for parting lines, draft angles, and surface finish.

- Material Selection: The choice of mold material is critical. Molds for car body components must withstand high temperatures and pressures associated with injection molding processes. Common mold materials include steel alloys like P20, H13, and stainless steel, selected for their durability and thermal stability.

For questions or more information on any of our finishes and custom coatings, or to get started on selecting the right finishes for your project contact us today:

Hot plate vibration machine

Hot Plate: A hot plate is a portable electric appliance used for heating objects or substances. It typically consists of a flat, smooth, and heated surface that can be adjusted to various temperature settings. Hot plates are commonly used in laboratories, kitchens, and various industrial applications for tasks like cooking, heating liquids, or conducting experiments that require controlled heating.

Now, if you are referring to a combination of these two concepts, it’s possible you are describing a specific type of equipment used in scientific or industrial applications where vibration and heat need to be applied simultaneously. Such equipment would typically be custom-designed for a specific purpose, and its function would depend on the specific needs of the application.

If you have a more specific application or context in mind for a “hot plate vibration machine,” please provide additional details, and I can offer more precise information based on that context.

For questions or more information contact us today:

Ultrasonic welding machine

Ultrasonic welding is a process that uses high-frequency vibrations to join thermoplastic materials together. It is a widely used technique in industries such as automotive, electronics, medical devices, and packaging.

Ultrasonic welding is valued for its speed, precision, and the fact that it doesn’t require additional materials like adhesives or fasteners. It produces clean and hermetically sealed joints, making it suitable for a wide range of applications. It is commonly used for welding plastics in industries where high-quality, efficient, and reliable joining methods are essential.

For questions or more information contact us today: